Material Grades

Flame Retardant Silicone Rubber

Adpol’s 40 years of experience manufacturing products for the aerospace industry means that we have a great deal of experience with Flame Retardant Silicone Rubber Compounds.

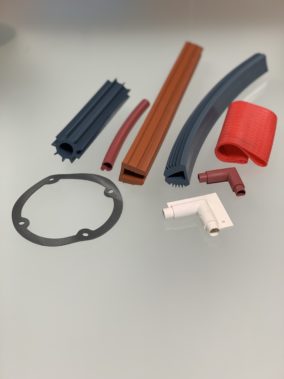

Silicone naturally is self extinguishing, and most of our general purpose grades meet UL94HB. But in certain specialist applications such as aerospace, rail and other mass transit even higher standards of self extinguishing and low smoke emissions are required from Flame Retardant Silicone Rubber.

Adpol manufactures in a number of Flame Retardant Silicone Rubber grades that meet UL94V0, ABD0031 and BS6853 and the halogen, toxicity and smoke emissions standards of the vast majority of airlines and train mass transit operators across the world. These compounds are available in a range of hardness’s and can be colour matched to your project requirement. We operate to the AS9100 quality systems and traceability levels required for products in these specialist sectors.

Adpol extrudes custom Flame Retardant Silicone Rubber seals that are often used as door, seat or bulkhead seals, either supplied as extruded profiles ( P tapes, D Profiles, e profiles , fabricated complete Silicone Rubber Gaskets, Silicone Rubber Sheeting and Strip, gaskets punched from sheet, or moulded silicone rubber parts, and adhesive backed if required

From drawing to sample for testing generally only takes a 2 – 3 weeks and costs £175 – £250

If you need any technical advice with a new or existing project, or would like a quotation please contact us and we will be happy to help.

Weather Resistant Rubber

Silicone Rubber is by some way the most weather resistant polymer and an excellent choice if you need a good seal in any application likely to see tough environmental conditions.

Silicone Rubber is an extremely versatile material offering excellent technical properties in harsh conditions. Silicone Rubber is highly resistant to UV light, Ozone, oxygen, salt, mold and mildew, and the general aging affects of weather. Other rubbers can harden and crack over time and support organic growth, you see this sometimes on old window seals which can be EPDM

There have been many tests over the years to demonstrate this, including control samples of Silicone Rubber being subjected to the extremes of the Arizona desert or deep Atlantic oceans for years without any significant loss in technical performance.

Adpol can help you develop the ideal seal for your application in weather resistant Silicone Rubber, as we have with many longstanding customers over the years. Please don’t hesitate to contact us to discuss your requirements, we are here to help.

High Temperature Silicone Rubber

Adpol extrudes and moulds products in an extreme High Temperature Silicone Rubber grade that is rated up to a maximum operating temperature of 300°C. This is available in a range of hardnesses from 30 to 80 shore A, and can be pigmented to almost any colour you could require.

Adpol can extrude High Temperature Silicone Rubber into Silicone Rubber tube and cord, Silcone Rubber Extrusions or Silicone Rubber Sheet and from this can form fabricated Silicone Rubber Gaskets or punched gaskets. A new extrusion die and sample will typically cost you £175.00 and take 2 – 3 weeks, prices therafter vary based on profile size and shape and volume. We can run jobs from 20m up to many Kilometers

There is also a range of High Temperature Silicone Rubber compounds available that have been specifically developed to meet food standards across most European States and the USA.

For more information, data sheets or to discuss your High Temperature Silicone Rubber requirements and receive a no obligation quotation please contact us. We will be happy to offer you technical advice to help steer you toward the product best suited to meet your application.

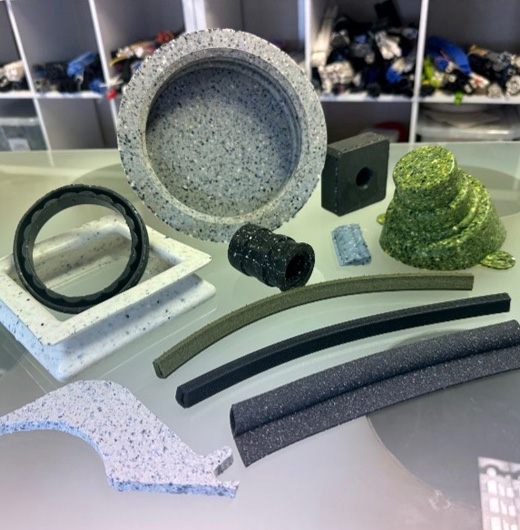

Silicrumb The Recycled Silicone Rubber

Recycled Silicone Rubber

Silicone’s extreme durability unfortunately doesn’t make it a raw material you would want to put into landfill, but tragically it’s where the majority of scrap Silicone Rubber ends up.

We estimate that in the region of 500 tons of Silicone Rubber a year will end up in landfill, where it will remain for hundreds of years.

Adpol has spent the last few years considering how to change this and economically recycle Silicone Rubber back into the manufacturing process. With the launch of the Silicrumb range of Recycled Silicone Compounds we are very proud to say we can now do just that, as possibly the first firm in the UK to do so.

Through a specialist process we can grind up the silicone and then re introduce it to compound at levels of up to 50%. For mouldings with walls over 2mm it works very well, and for extrusion with walls over 3mm it also works well giving amazing colour mixes and textured finishes.

The added beauty of this is that the recycling of the Silicone Rubber can be repeated over and over again, so you can ask your customers to return the seal to you, and then us for full cycle sustainability.

By encouraging more firms and more customers to support this initiative we can keep Silicone Rubber out of landfill, and reduce the emission heavy process of making and shipping Silicone Rubber around the globe.

We are already working with a number of firms who have successfully introduced recycled Silicone Rubber products to their product lines and are keen to go further with positive support from customers.

Please join us in this new initiative at the very beginning and get in touch so we can discuss how we could introduce this green initiative into your manufacturing and sales processes.

Food Grade Rubber Seals

Adpol manufactures food grade rubber seals and fda grade rubber gaskets and mouldings for leading companies across the world.

Our compounds meet FDA, WRAS, BFR, and WRC regulations and we can provide full certification with orders. Compounds also go as far to meet USP Class VI which is a medical standard, can cope with extreme high and low temperatures, be extreme high tear strength and be metal loaded for in line detection.

Available in custom colours, hardness’s, and shapes please contact us to discuss your project or requirements and we will be very happy to assist.

Steam Resistant Silicone Rubber

One of the applications where rubber seals or tubes are often required is where steam is present, often at high temperatures and pressures. Most rubbers do not cope well with Steam and degrade quickly, Silicone Rubber is no exception.

Steam Resistant Silicone Rubber has been specifically developed with resistance to steam and will last considerably longer and perform better than other grades of Silicone Rubber.

Adpol manufactures extrusions, mouldings, gaskets, seals and punched parts from a specialist steam resistant compound. We are able to vary the hardness and colour to suit your specific needs.

A new extrusion die and sample can cost as little as £175.00 and take from 2 weeks with order volumes from 20 – 20,000 metres being catered for thereafter.

Please don’t hesitate to contact us for a quote or to discuss your technical requirements. We are a family run business passionate about looking after our customers and building solid long lasting relationships.

Conductive Silicone Rubber

Adpol’s AP701/2 grade is a good quality and well proven semi conductive carbon loaded grade of Silicone Rubber used extensively in EMC or static shielding and sealing applications.

We can extrude this compound as tube, cord, complex hollow and solid profiles to customers design and supply these as cut lengths, cut and joined into O Rings, or square gaskets.

A new die and sample typically costs £225.00 and takes 2 – 3 weeks

We can also extrude this as sheet which can be converted into flat cut gaskets, either through punching or water jet cutting with or without adhesive backing.

We can also offer a UL94HB certified grade if required.

Please don’t hesitate to contact us to discuss your requirements or get a quotation.

Low Temperature Rubber Seals

Adpol can manufacture custom seals designed to operate as low as -100 degrees C working with you to ensure the size, hardness, colour and other properties like tear strength and chemical resistance are exactly what you need

Rubbers harden as the temperature drop, Silicone Rubber performs best at extreme high and low temperatures. Our general purpose silicone (food and medical grade) will operate down to -40/-60 area without much problem. If you need extreme low temperature resistance we have a specialist grade designed to operate at -100. All silicones also offer excellent resistance to mould, mildew and microbiological growth

We can extrude tube, cord or profiles that can be cut and press joined into O rings or picture frame seals, mould parts, and can have gaskets cut from flat sheet for you

We have many years experience in this sector and would be very happy to work with you every step of the way to help you get exactly the seal you need. Please get in touch to discuss this further

Thermally Conductive Silicone Rubber

Adpol can mould and extrude in a grade of thermally conductive Silicone rubber which offers performance approaching copper loaded silicones, but at a fraction of the price.

Our 60 Shore A grade of thermally conductive Silicone rubber offers a thermal conductivity value of up to 1.13W/(mk) compared to standard Silicone 0.24. We have successfully extruded small profiles and tubing in this compound and would be happy to look at your custom projects in this grade.

We will also be able to cut and join thermally conductive Silicone rubber profiles and tube in this compound into O Ring or Letter Box gaskets.

This compound can be extruded into P tapes, D Profiles, e profiles and adhesive backed if required.

Traditionally metal loaded compounds have been the best solution when looking for thermally conductive polymers. But these can be very expensive and restrictive in terms of the hardness’s available, thermally conductive Silicone rubber offers a fresh approach to this area.

Please don’t hesitate to get in touch for quotations or technical advice if you think there is a new or existing project we can help you with.

Anti Bacterial Silicone Rubber

Silicone Rubber naturally possesses anti Fungal, Microbial and Bacterial Properties that can be further enhanced with specialist additives to give excellent resistance to MRSA and EColi, which can be extremely beneficial in certain applications.

Adpol can extrude custom profiles and strips in a wide range of Silicone Compounds and the above properties plus Silicone’s soft and stretchy nature make it an ideal choice when requiring latex free straps for clothing or PPE in Medical applications

We can extrude your custom strips and punch out straps to your exact requirements. We can also extrude seal profiles and join into complete gaskets where needed, and mould custom parts, including rubber to metal composites

Please just ask us for more information, prices or samples

Fluorosilicone Rubber

Adpol manufactures Fluorosilicone Rubber extrusions, tubing, punched gaskets and moulded parts.

Fluorosilicone Rubber (or FVMQ) offers excellent resistance to chemicals, fuel, oil and acid resistance and is the ideal choice in extreme operating environments. Our Fluorosilicone Rubber compound is available in a 60 Shore A hardness, with an operating temperature range of between – 60 and + 225 degrees Centigrade. Adpol can also manufacture in a 50% blend, to reduce costs which is quite suitable in some applications.

Adpol can manufacture Fluorosilicone Rubber products in a wide range of colours and to meet customer requirements from drawings or samples, simply get in touch to discuss your requirements and let us offer you advice, and a quotation if needed.

Short runs (from 50m) at sensible MOQ prices to many kilometres on reels are all available, along with high quality standards from an established and approved life science supplier, good service and high levels of customer support.

Please contact us for a quotation, to discuss your requirements or place an order.

Metal Detectable Silicone Rubber

Metal detectable silicone rubber is increasingly being used in the food, drink and dairy industry to reduce the risk of rubber parts ending up in products.

Metal detectors situated on the production line identify the metal fragments and stop the line to prevent any metal parts contaminating the food product.

Adpol already manufacture a wide range of extrusion types, tube and cord in metal detectable silicone rubber we have the ability to customise the hardness and colour to suit your exact needs

We can reverse engineer to existing profiles or work to customer drawings. In addition we can supply cut flat gaskets from metal detectable rubber sheet in a range of thicknesses, or the sheet just on its own.

Self Lubricating Rubber

Adpol can mould self lubricating Silicone Rubber parts that can operate at extreme high and low temperatures and offer many significant performance advantages over standard Silicone.

Through the addition of a special additive the Silicone exudes surface lubrication over time giving an extremely low friction surface. This offers many advantages over standard Silicone which may become tacky and stick against other surfaces, or itself.

Custom parts can be moulded or gaskets can be cut from moulded sheets in various thicknesses. We developed and have been working with this compound for many years. For technical advice, quotations or samples please get in touch and we’d be very happy to assist.

DTD Specification Silicone Rubbers

Adpol has been extruding and moulding in many different rubber grades since 1974 for Military, Aerospace and transport applications and is well versed in some of the DTD and other material specifications on drawings for rubber parts.

Common specifications that are still used are DTD 5531 DTD 818 and DTD 5582. Often quoted with prefixes after the main code which are important as these will denote the hardness and other unique performance factors.

Many drawings still call for DTD specifications and overlooking the specific requirements of the standard quoted can be dangerous. Adpol can source and manufacture in rubber grades that are either designed to meet, or tested to the required DTD specification with full certification and traceability up to our AS9100 quality standard.

Please don’t hesitate to contact us with details of your requirements no matter how obscure, and we will be happy to help you find a solution.